The ports AI revolution is here – and her name is Veronica

Ready for action – or soon to be – are SOPHIE, AMBROSE, ABRAM and ATLAS, to name a few.

For decades, nGen, Hutchison Ports’ proprietary Terminal Operating System (TOS), has been a world leader in algorithmic-driven TOS management. But the AI revolution is driving the modernisation of the current systems and nGen will be completely phased out by 2030.

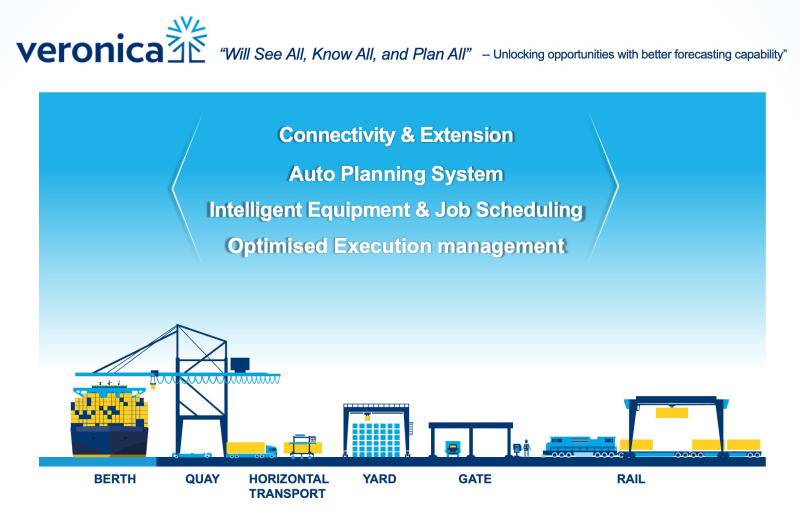

Veronica, the new TOS, still uses an algorithmic level of calculation, but then uses modern AI on top of it to max out productivity. Deep learning has been applied to the masses of data accumulated by global port operations to make the movement of containers an even more graceful ballet. Early AI only focused on a narrow function, for example loading and unloading from ships, movements in the yard or container storage. This coordination was cutting edge for its time, but times change. Veronica will see all, know all and plan all.

AI revolution is driving the modernisation of the current systems and nGen will be completely phased out by 2030.

On the waterfront

Ships en route to port digitalise their manifests (a record of all cargo on board) in advance; by this time, Veronica is already at work. Hutchison Ports Digital Exchange (HPDX) manages the Electronic Data Interchange (EDI) and interprets data from the blockchain. A new AI platform, Documentation Digitalisation, standardises documentation processes; it also classifies and digitalises key info from emails automatically. Together, HPDX and EDI empower communications between the logistics community and Hutchison Ports. They also provide scalability to support data processing for multiple ports globally. Soon, when ships arrive, Veronica's subordinate AI systems, ABRAM and AMBROSE, will perform tasks like deciding how berth-side resources are deployed to best effect. Their names are, as one might suspect, acronym influenced. ABRAM, for example, is derived from “Augmented Berth and Resources Allocation Model” and AMBROSE is “Activity Model Based Reinforcement Operational Stowage Engine”.

Veronica is special – her name isn’t an acronym and was chosen to personalise the system and give it a human touch. She also watches over her children, the yard-management systems SOPHIE and ATLAS, which direct autonomous trucks that have their own onboard AI to carry out the orders from Veronica’s planning system.

Veronica still uses an algorithmic level of calculation, but then uses AI on top of it to max out productivity.

Move it, move it

Herman Chiu, General Manager of Terminal Development, Hutchison Ports, is directing the efforts to use AI embedded in vehicles and facilities to transform operations.

Some remote control gantry cranes have remote, human operators who partner with AI to guide their movements and avoid mishap, even in the dark of night. Self-operating cranes loom like the Recognizer in Tron, the classic Disney film that showed a 1982 vision of the inside of a computer. Aside from operating themselves, auto-gantries can tell a human driver that they have improperly parked or mis-released a container, thereby avoiding accidents.

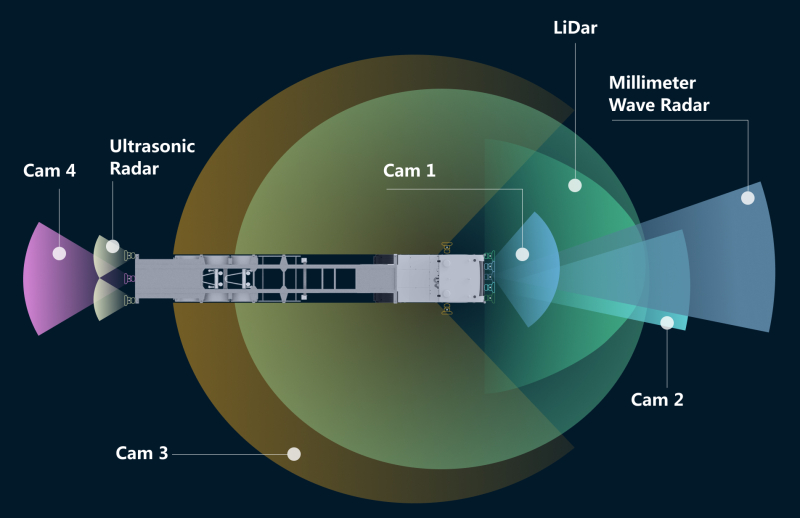

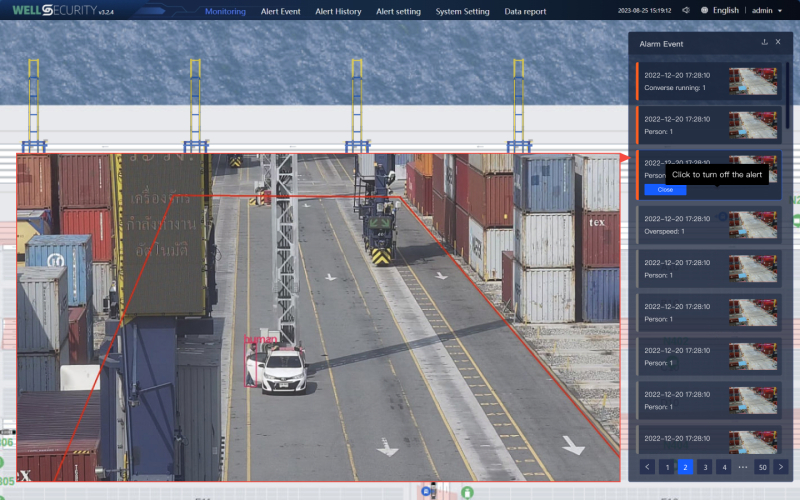

The most advanced ports have arrays of cameras and Internet of Things (IoT) sensors that can see the space and motion of every vehicle and know where they are going. These inform a traffic management system, V2X, that uses real-time data to inform the planning and management system for autonomous trucks (ATs). Hutchison Ports Thailand hosts some of the most advanced autonomous truck systems; Mexican, Egyptian and UK ports are soon to follow. The same CCTV system’s AI can detect suspicious or dangerous behaviour in the yards – such as truck drivers getting out of their vehicles in areas where it is unsafe to do so, or a person not wearing their safety vest and helmet.

Cranes and ATs in the yard will soon get their directions from SOPHIE and ATLAS on where to go and how to stack containers. Connectivity to the outside world, via truck and rail, will be mediated by the rest of Veronica’s family as the Hutchison Ports team, led by Edmund Wong, Operations Development Director at Hutchison Ports, determines which sibling is ready to take up a new role.

A holistic view

The aim is to have a TOS that not only can organise the fastest loading or unloading of a ship, or the optimal placement of a container in a storage stack in the yard, but one that considers the productivity and cost-effectiveness of the port operations as a whole.

Real people are still making the final decisions based on the insights provided by the new TOS, but over time, the amount of useful data will combine with the capabilities of improving AI to make real-time decisions beyond the scope of human processing power. Weather, the daily price of oil, diesel or hydrogen and the location of every inbound truck, ship, container and staff member are just a sliver of the multitude of factors to be considered.

Ultimately, the positive effects – from faster service to lower costs – impact the whole supply chain, saving consumers money and driving economy-wide productivity improvements. Hutchison Ports has been at the forefront of using AI advances to improve safety, efficiency and service and will lead the cutting edge to the end of the decade and beyond.

The aim is to have a TOS that ... considers the productivity and cost-effectiveness of the port operations.