COVID-19 containment: Watsons Water makes a mask-making miracle machine

From pure water to pure mask protection

Watsons Water actually had its origins in a pandemic. In 1903, the firm was founded to provide a clean, trusted source of drinking water during an era of recurring and debilitating bouts of the plague. Yes, the plague.

Modern Hongkongers are no stranger to contagious disease outbreaks. Ever since the SARS outbreak in 2003, the slightest sniffle has been cause for responsible citizens to ‘mask up’ with no debate. Demand for masks immediately went through the roof in January 2020 as citizens took individual measures to protect themselves and their communities from the coronavirus pandemic.

As Asian countries and then the rest of the world followed suit, the demand for personal protective equipment (PPE) rapidly outstripped supply. Masks were at top of the list. The team members of constituent A.S. Watson Group (ASW) companies came together to see what they could do to help.

They quickly identified an opportunity. They realised that they had expertise in clean environment manufacturing and a factory in the Watsons Water operations on an industrial estate in Tai Po, in Hong Kong’s New Territories. The facility wasn’t equipped to make masks – but it could be reconfigured to do so through the combined expertise and commitment of the Watsons Water team.

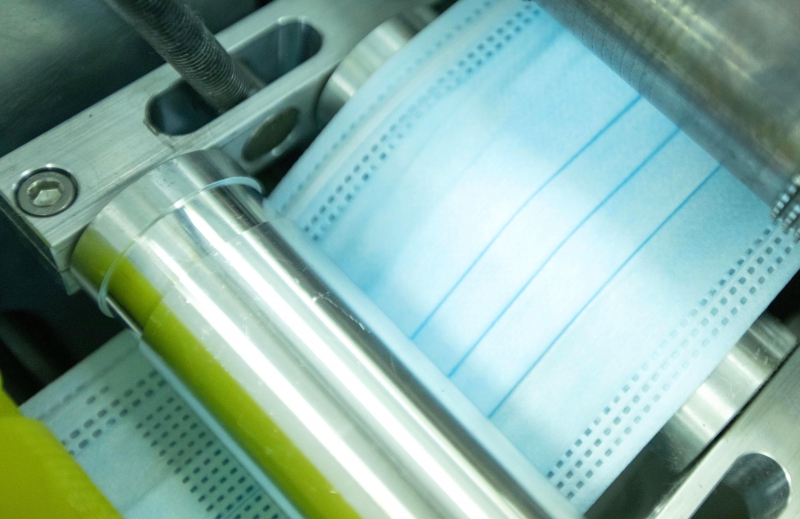

Twenty engineers addressed a complex range of issues, including sourcing mask-making machinery, raw materials and packaging. They quickly acquired technical expertise to support the installation of equipment and determined how to transfer their know-how from beverage manufacturing to mask-making. Expertise in ISO standards, project management and manufacturing was transferable to the new effort.

How do you 'turn a bottled-water production plant into a mask-making miracle machine'?

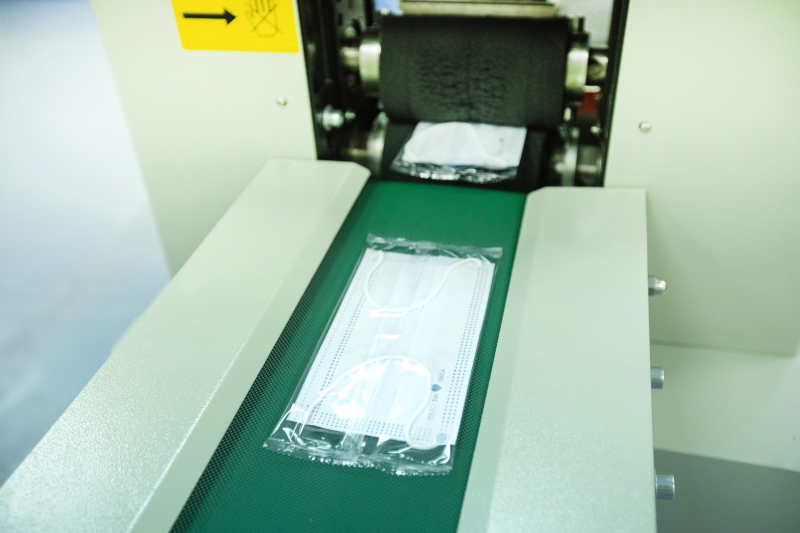

In just two months, part of the water-bottling plant was converted into a dust-free clean room (meeting ISO14644-1 Class 8 standards), and now 10 automated production lines are running 24 hours a day, producing 10 million masks a month. The new Watson’s masks meet the ASTM Level 2 and 3 standards that detail fit and filtration effectiveness requirements.

It wasn’t easy, and early production hiccups had to be corrected. Engineers worked around the clock to bring the supply online. This enabled Hongkongers to mask up faster, helping to stem contagion in Hong Kong and to save lives.

For the people

ASW staff, especially in high-contact, front-line roles at Watsons and PARKnSHOP, were first in line to get masks to protect their ability to carry out core functions and keep the PPE flowing to the public. The same applied to business partners in the supply chain. Charities catering for especially vulnerable populations were also among the earliest recipients.

Distribution and marketing expertise ensured the masks made it to the public through Watsons retail outlets. Marked with a ‘ASWI We Care’ slogan, the masks conveyed not only ASW’s care for their customers but also helped mask wearers remind people around them that mask-wearing wasn’t just for the wearer – it also helped protect everyone around them.