Drones: taking the danger out of ensuring safety, from sea to sky

From offshore oil-processing platforms to underground electric cable tunnels, ensuring safety requires inspections that are hugely expensive in terms of time and money. Once a generation, a new technology arrives on the scene which is a game-changer, improving not only the efficiency but also the quality of safety inspections. One such technology has come to the fore: enter the drone.

From sea to sky

The SeaRose FPSO (floating, production, storage and offloading) vessel works 350km offshore from Newfoundland and Labrador, Canada. The ship has to be where the oil is, but being so far at sea in the North Atlantic involves some challenges when it comes to preventive maintenance.

One of those challenges is in inspecting the ship from the hull under the sea to the flare tip. The flare tower enables operators to conduct a controlled burn of hydrocarbons in the event of excess pressure in the pipes. For safety, the flare tip is high above the ship – over 100m high! Like all areas of the FPSO that are subject to wear and tear, it needs to be inspected regularly to ensure it’s operating safely. Today, that work is done using aerial drones.

Prior to using drones, aerial inspections took place from helicopters. In order to do the inspection safely, the photographer would shoot from the partially open door of the helicopter, tethered inside and with a search and rescue technician on standby to ensure his or her safety.

The first offshore drone flights became possible in 2018, eliminating the need to put a dedicated flight in the air for inspections, and making it easier to conduct inspections more frequently, more safely and at a reduced cost. As drone and camera technology develops, the ability to get even more detailed inspections can only improve. For example, Cenovus engineers are working on adding methane detectors to the next-generation drones. The company employs the DJI Matrice 300 RTK drone combined with the Zenmuse H20T Quad-Sensor. While this drone is state-of-the-art today, Cenovus is constantly upgrading its technology.

From the top of the flare tip to the interior of the deep tanks that hold the oil, drones are helping. Prior to drones, staff would inspect the empty holding tanks by entering the tanks themselves. Now drones can make the trip. Small enough (40cm diameter) to go into a standard manhole, drones started inspections at the end of 2019. The Elios 2 UAVs (unmanned aerial vehicles) are enclosed in cages to protect them from bumping into walls.

Drones can also conduct inspections on the exterior hull of the ship, as well as on the helideck, exhaust stacks, cargo tanks and ballast tanks, among other spaces.

Cenovus engineers are working on adding methane detectors to the next-generation drones.

Into the deep

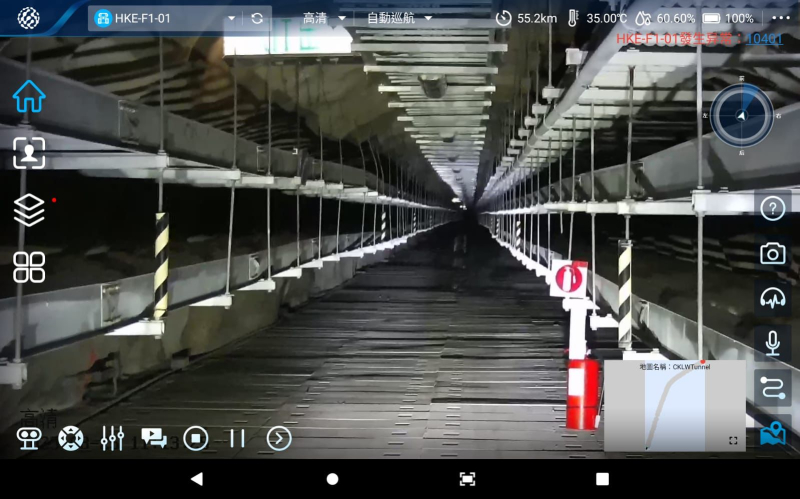

HK Electric is also using a land drone to improve the safety, quality and frequency of inspections, but in their case, underground! They have partnered with Hutchison Telecom Hong Kong to install 5G receivers in a confined cable tunnel carrying high-voltage cables, which help to maintain a world-class level of supply reliability and stability.

Inspections by maintenance staff used to take place either regularly or after extreme weather to ensure the integrity of cable tunnels. However, such check-ups require many people-hours of preparation and execution. As required by the law and the company’s safety policies, engineers entering these confined tunnels have to be supported by other certified workers and colleagues at the entrance to provide first responder backup and ensure no unauthorised access.

Now, the 5G “Smart Inspector” Robotic Solution does the tunnel crawling. It stands about 1.5 metres tall (about five feet) and has four wheels; like Wall-E, but taller! It is loaded with cameras and sensors that take a very close-up look at various elements of the cables and other equipment in the confined tunnel. An infrared camera can see the heat signatures and detect overheating. A high-definition camera can take a closer look at elements flagged by the standard cameras. Sensors and gas detectors capture images and record gas concentrations, humidity and temperature within the tunnel. The robot can also be remotely operated on 5G, and even has preset working schedules to automate tasks.

Now, the 5G ‘Smart Inspector’ Robotic Solution does the tunnel crawling.

The Smart Inspector is now doing the job independently and automatically on a routine basis as required. Data and camera feeds can be remotely accessed and monitored in real time via the high-speed 5G network. Given the enhanced efficiency and quality, HK Electric is planning to expand the coverage to other confined tunnels as much as possible.

Drones have proven hugely useful in making needed inspections safer, faster, more frequent and of higher quality. CK Hutchison companies such as Cenovus and HK Electric are showing that from sea to sky to subterranean, drones are the way forward!